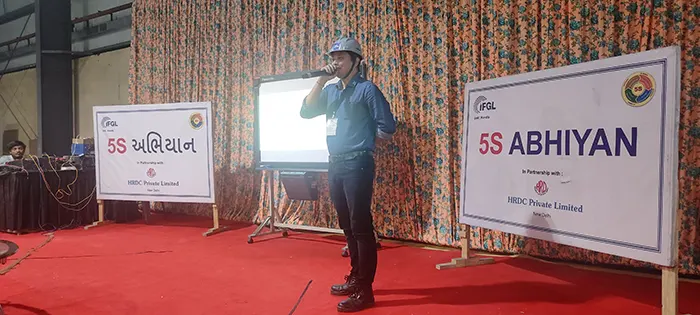

5S

- Training

- Audits

- Handholding & Implementation

- Revamping

- National Awards Participation

- Developing 5S Auditors, Trainers and Implementors

- 5S Implementing Materials (5S Store)

Plant Safety / Behaviour Based Safety (BBS)

- Training (Fire, Electrical, Chemical, Material Handling)

- Audits

- Competitions & Rewards

- Assessments

KAIZEN

- Training

- Developing KAIZEN Champions

- KAIZEN Policy

- KAIZEN Compilation, Measurement & Rewards

Cost Reduction Programme (CRP) / War Against Wastage (WAR)

- Training

- Implementation

- Measuring Savings and Rewards

Quality Circle / Problem Solving Tools

- Training

- Team Formation

- Evaluation of Results

- Rewards & Recognition

- Preparation & Participation in QC National Competitions

Client Testimonials

Client satisfaction is our ultimate goal. Some of our delighted Clients have a shared a

few kind words to express their satisfaction with service. Here is what they have to say.